Products and Services

Protective Films

It’s everywhere!

Think about it. When was the last time you bought something that it didn’t have a protective film covering on it? Microwave ovens, cars, watches, cell phones, even our sunglasses have film on them. And very often that film originated here at Jacobsen Industries.

If you and your team have something that you want to protect, we can help. We stock everything from cling film to transit masking.

As one of the powerhouses in Protective Films, Jacobsen Industries welcomes the opportunity to help you with your protective film needs. Whether it be a painted surface, a wooden door, a new car, or an appliance, with our wide variety of Protective Films, we can help you find a solution.

With our trusted, qualified vendors we can even test your part to our films.

Perforated Rolls or Custom Die-cuts

Our state of the art converting technology allows us to offer our customers an infinite number of possibilities for delivery. And the speed at which we convert helps keep the costs down.

Our newest addition is a 30” wide, mid-web, Rotary Press, one of the widest in the country. We can spin your custom die-cuts at speeds of up to 350 feet a minute.

Call us today for a quote, because chances are, if you are calling someone else, they are going to call us anyway!

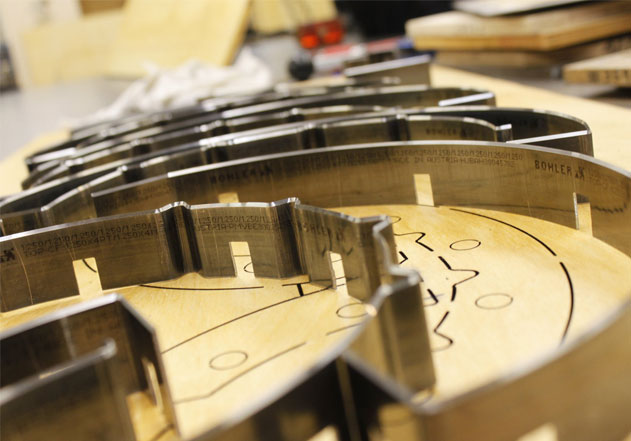

Die Cuts

The foundation of what we do!

Die-cutting is the process of creating a custom shape using a tool. Parts can be converted from foams, films, adhesives, plastics, metals, rubbers, and numerous other materials.

Die-Cut parts can be produced in a variety of ways. At Jacobsen Industries we have a variety of converting equipment that allows us to make your part in the most cost effective way possible.

We can also work directly with you and your team on a delivery method that best suits your needs. We can manufacture parts as trim cut (individual pieces), kiss cut on a roll or sheets, scatter packed in bags, on strips, and many other ways.

Steel Rule Die-cutting is a common process used to produce parts from a wide range of sheet and roll materials, including paper, cardboard, rubber, and plastic. Steel rule die tooling is cost-effective, fast, and can make thousands of parts before a re-rule is needed. Prototype parts are often tweaked using steel rule dies before moving on to high volume, rotary tooling

Need millions of die-cuts parts? Die-cuts that require large volumes are produced most-efficiently with rotary presses. Jacobsen Industries leads the way in the rotary department, with die-cut widths as wide as 30” possible.

Need large thick die-cuts from wide rolls of heavy material up to 1200 pounds? It’s not a problem with our computer controlled automatically-fed conveyor presses.

As a customer of Jacobsen Industries, we promise to maintain your die in optimum working order and continue to do so, for the life of the program, on our nickel, not yours.

Steel Rule Dies

Jacobsen Industries was established in 1946 as Jacobsen Steel Rule Dies.

Our founder, Frank Jacobson, started building steel rule dies shortly after serving in World War II. Today we continue to offer the same service and quality that Frank insisted on over 60 years ago.

Steel Rule Dies are used in die cutting a range of sheet and roll materials including paper, plastic, cardboard, rubber, foam and numerous others. Steel Rule Dies can be made to cut nearly any shape, as a matter of fact; puzzles are cut with Steel Rule Dies.

Jacobsen Industries make steel rule dies for the “trade” as well as for our own “in-house” needs.

Customers tell us what they want to make, and we make it happen. Have sample material? Send it along with your die order and we will make samples, using your material, to ensure that the die and part are to spec.

Our in-house CAD capabilities, allow us to have the die boards cut directly from your data, ensuring an accurate die-cut. We can accept many forms of data file but prefer DXF, DWG or PDF. The tool room can turn around most tooling within a week, but we can also offer a quicker turnaround if needed.

Prototypes as well

Many of our customers bring in a hand cut sample or the part that they actually want a die-cut for, and we work with them to come up with a solution.

Adhesives and Tapes

Modern adhesives are stronger than ever!

In many situations, adhesives are taking the place of traditional bonding methods. We can even offer adhesives that can be die-cut and are so strong that they can take the place of a weld.

Jacobsen Industries can help you find the bond that your team is looking for, whether it’s to hold an emblem to a car or as an aid in assembly. We have the resources to find the solution, and chances are that we’ve solved your problem before.

As a 3M Select Converter, we are specialists in Acrylic Foam Tape. 3M makes the best Acrylic Foam Tapes in the business, and you can find them all here. We convert them every day for a wide variety of applications from body side molding to seals on LED lights.

Not too long ago, emblems were held on with mechanical fasteners and were a prime location for rust. Today die-cut foam tapes hold them securely to the body of the car, and rust is no longer an issue.

Rolls or Specialty Converted

Jacobsen Industries can supply you, and your customers, with Adhesives in rolls, sheets or Die-cut to shape. Feel free to give us a call or send us an email and we will get to work on your solution.

Rubber Bumpers

Ever wonder where those little rubber bumpers in your glove box, or center console, come from? Jacobsen Industries supplies Rubber Bumpers to the Automotive Industry by the millions. We inventory a large variety of Bumper styles and share our buying power with all of our customers both big and small.

Have a new design? We can custom make them for you as well.

Rapid Prototyping

Anyone can quote the job in two or three days, but can they present you with a prototype part? We can.

Our in-house tooling capabilities and vast inventory of materials allow us to help you with that initial design or emergency need.

Not sure what material will work? Let us help you with that as well. We can provide numerous options for your initial trials. Our suppliers know that this is how we work, and they support it. If we don’t have a specific material in house, we can, very often, get a sample quickly.

We can, and will, support you and your team from prototype through production.

Packaging

Packaging, driven by the supply chain and increasingly influenced by the consumer, is more than ever a critical factor for brand strategy. At Jacobsen Industries, we excel in packaging design, testing, and optimization for displays, retail packaging, and shipping platforms. We have packaging engineers on staff to develop the best solutions for our clients.

Professional Services

For 70 years, the Jacobsen brand has been our reputation. Our Professional Services team will work with you to realize top efficiencies in packaging, product application, and workflow analysis.

Our Professional Services team will work with you on site and leverage our experience to optimize workflow, implement solutions, and help you increase revenue streams.

- 1

- 2

Recent Comments